Swift Marine Tech Services Pte Ltd

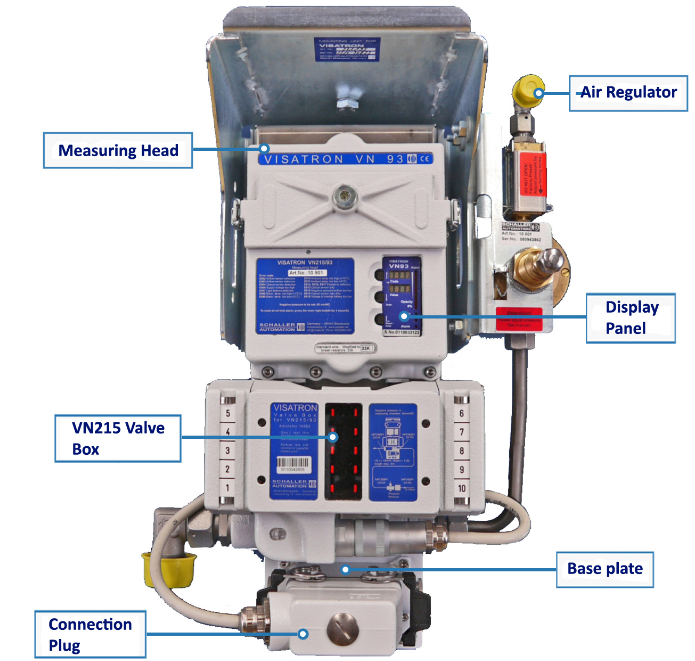

Schaller Visatron OMD

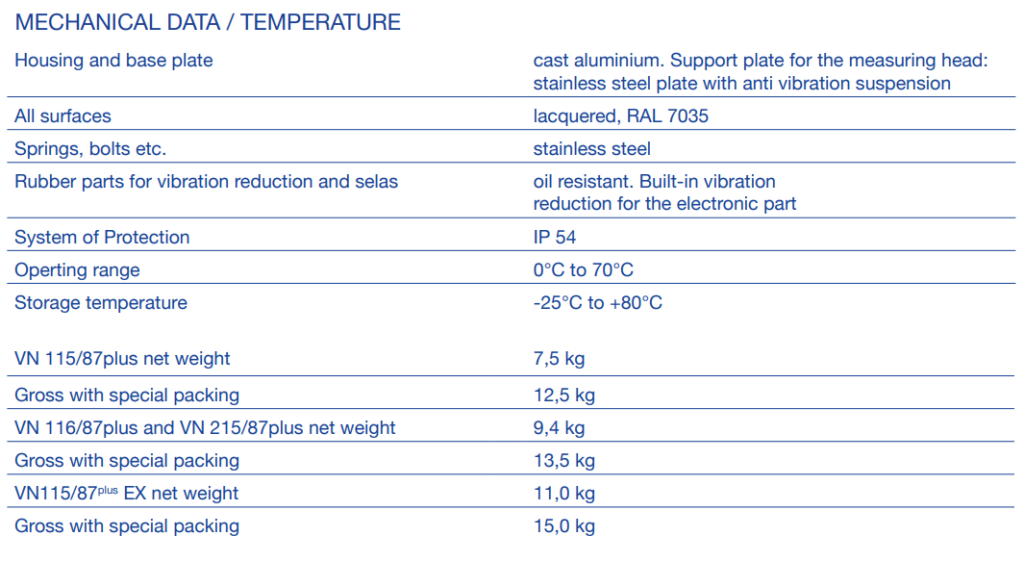

VISATRON® oil mist detection systems utilize infrared turbidity measurement for continuous monitoring, featuring durable, interchangeable components with built-in protection against contamination and condensation. These detectors play a crucial role in safeguarding large Diesel, Gas, and Dual Fuel engines from severe damage caused by oil mist explosions, often resulting from overheated bearings or moving parts. Schaller VISATRON® systems ensure continuous crankcase monitoring across all engine compartments using a specialized suction-based system, powered by a wear-free air jet pump that operates on compressed air. Widely trusted by engine manufacturers and shipowners, this proven technology delivers high operational reliability with significantly lower maintenance costs compared to conventional systems.

Key Features

- Multi-Stage Alarm System: Equipped with three relay outputs for system readiness, pre-alarm, and high oil mist alarm, ensuring early detection and timely response to potential hazards.

- Continuous Crankcase Monitoring: Uses a suction-based system powered by a wear-free air jet pump to continuously sample and analyze the crankcase atmosphere.

- Infrared Optical Measurement: Measures turbidity levels in the sample flow through infrared light absorption, offering highly accurate detection of oil mist concentration.

- Scavenging Air Chambers: Protects the optical system by using pressurized air, preventing dirt contamination and extending the lifespan of filters.

- Condensation Prevention: Built-in heating unit in the measuring head prevents condensation, minimizing false alarms caused by humidity.

- Remote Monitoring Capability: Features RS 485 interface for seamless integration with remote monitoring systems and an alternative 4-20 mA connection option for enhanced flexibility.

- Pre-Alarm Functionality: Activates a pre-alarm at 70% opacity, offering early warning before reaching critical oil mist concentration levels.

- Adjustable Alarm Sensitivity: Provides four sensitivity levels, allowing operators to customize the system for optimal performance based on engine conditions.

Benefits

- Enhanced Engine Protection: Detects oil mist at an early stage, preventing catastrophic failures and costly repairs.

- Increased Reliability: Non-wearing air jet pump and contamination-resistant components ensure long-term, trouble-free operation.

- Accurate Damage Localization: Identifies the affected half of the crankcase, allowing for precise troubleshooting and targeted maintenance.

- Lower Maintenance Costs: Self-cleaning mechanisms, contamination prevention, and remote monitoring capabilities reduce manual inspections and extend component life.

- Compliance with Safety Regulations: Meets stringent maritime safety standards, ensuring regulatory compliance for engine manufacturers and ship operators.

Swift Marine Tech Services Pte Ltd

We Are Here to Help You 24x7

Trust our expertise for precise services and genuine new products. Contact us today!